2007 Gold Circle Award category:

Innovative solutions - Reroofing

Project:

Eilenberg-Tarter residence, Cardiff by the Sea, Calif.

Roof system type:

Zinc-coated copper with standing-seam panels

Movie of Photos - Click Here - 1.4 MB Windows Media

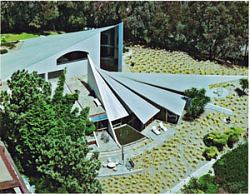

In Cardiff by the Sea, Calif., a house is perched on a bluff above the San Elijo Lagoon, which is an ecological

preserve for migratory birds. The house's unique roof has eight equilateral triangular roof segments in two

wings, and each of four segments is a different roof slope with a tapered clerestory window separating the

windows and window flashings from the roof.

In Cardiff by the Sea, Calif., a house is perched on a bluff above the San Elijo Lagoon, which is an ecological

preserve for migratory birds. The house's unique roof has eight equilateral triangular roof segments in two

wings, and each of four segments is a different roof slope with a tapered clerestory window separating the

windows and window flashings from the roof.

When the homeowners needed a new roof system for their house, they chose Keystone Roofing Inc.,

Oceanside, Calif.

Go with the flow

The existing roof system was standing-seam painted steel material installed perpendicular to the eave line.

"The roof was about 18 years old and badly deteriorated because of the nearby harsh saltwater environment,"

says Mark Katona, chief financial officer for Keystone Roofing.

"The roof was about 18 years old and badly deteriorated because of the nearby harsh saltwater environment,"

says Mark Katona, chief financial officer for Keystone Roofing.

The company was asked to install Revere FreedomGray™ 16-ounce zinc-coated copper.

"Its unique light-gray color and marine environment durability made for a perfect marriage of aesthetics and function," Katona says.

The architect for the project, Wallace E. Cunningham, owner of Wallace E. Cunningham Inc., San Diego, chose a herringbone design

pattern for the home for aesthetic purposes.

"When installing this roof system, it was challenging to provide a weather-tight roof system integrated with the tapered

clerestory windows, which intersect the roof at the beveled, metal-clad rakes and roof-to-wall transitions," Katona says.

"It was necessary to dismantle the existing roof and entire window system, installing a new system in its place."

Keystone Roofing and Custom-Bilt Metals produced the Revere FreedomGray metal panels, which were a 20-inch-wide Titan® CS-100 cap seam profile.

The geometry of the roof made the project more challenging.

"Making the panel seams watertight while essentially diverting or skewing water from its natural gravitational flow parallel down

each segment of the roof was an obstacle," Katona says. "Because of the skewed herringbone pattern, the water flow would be

channeled to the seam caps, especially during a heavy rain. An elaborate combination of two layers of GAF Materials Corp.

Stormguard® underlayment, butyl tape, panel interlocking and expert soldering at seam transitions were used to execute this

unconventional panel installation."

The companies also had to find a way to fabricate and move seamless panels, some of which were 65 feet long.

"The team roll-formed the panels on-site and rigged elaborate means of staging to maneuver such large and delicate panels,

undamaged, over a seemingly impossible terrain and steep-slope building configurations," Katona says.

A thing of beauty

Katona says the new roof is a masterpiece.

"Far beyond functionality, we believe we have achieved something special that not only helps keep our

environment pristine but creates a beautiful structure with a functional life," he says.